THE ANAGI

TRAY DRYER

Background

The Cashew nut is one of the most popular edible

seeds in the world and can be enjoyed in many forms

(raw, roasted, cooked etc.) Sri Lanka is home to some

of the best varieties of cashew and cashew related

activities are widespread. Cashew does not grow

everywhere, but its processing activities can be done

at any location. The initial processing (drying,

decorticating- or removing outer shell, removing testa -

inner shell) is a done mainly by rural women. In order

to make the removal of the outer shell more efficient,

it is necessary to dry or oven the cashew nuts. In a

traditional system, the “hot cupboards” or the ovens

belong to the middlemen or the “mudalalis”. They

sell the raw cashew to the women who decorticate

them and bring them to the mudalali for ovening.

The hot cupboards need electricity, and a substantial

quantity of cashew for ovening. The placement of the

electric coil causes uneven heating which leads to

irregular drying which causes some wastage in the

drying process. These features make it uneconomical

to micro scale cashew processors*.

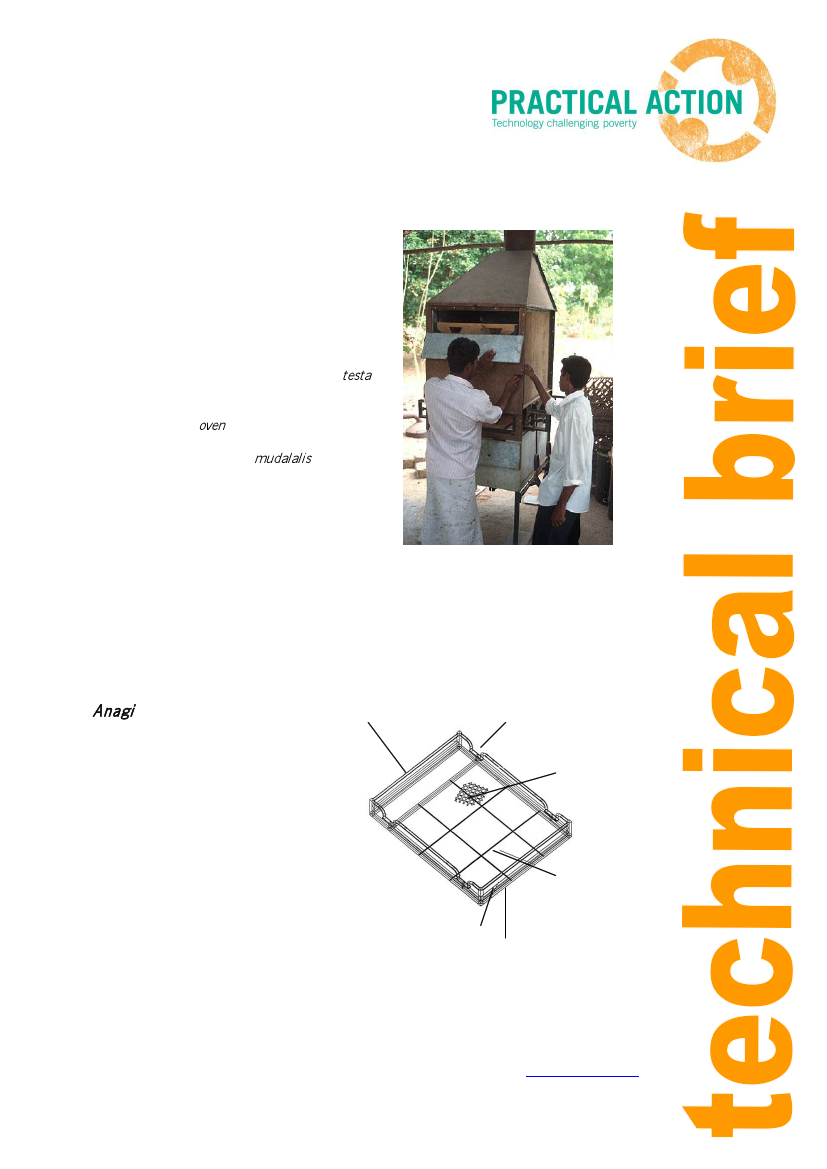

Figure 1: The Anagi tray dryer. Photo:

Practical Action South Asia

A group of women who were involved in cashew processing requested Practical Action South Asia to

develop a dryer that was suited for their purposes. The dryer was developed along with the inputs

from these users.

The Anagi Dryer

¼” x ¾” mild steel

flat strip

¾” dia mild steel light duty

hollow tube

This dryer comprises a drying chamber that

includes six trays, a furnace, a heat exchange

system and a lifting mechanism for the trays.

The drying chamber is made out of chipboard or

timber planks (externally) lined with aluminium

sheets both internally and externally. This

arrangement reduces the heat loss and ensures

that there is an even temperature inside the

chamber.

It has a dome-shaped roof enhances the out

flow of moist air.

½” x 2 ½“ „Albeasia‟

timber frame

Figure 2: The tray

mesh

¼” dia mild steel round

bar

¾ “ x ¾ “mild steel light

duty hollow box

Practical Action, The Schumacher Centre, Bourton on Dunsmore, Rugby, Warwickshire, CV23 9QZ, UK

T +44 (0)1926 634400 | F +44 (0)1926 634401 | E infoserv@practicalaction.org.uk | W www.practicalaction.org

___________________________________________________________________________________________________________

Practical Action is a registered charity and company limited by guarantee.

Company Reg. No. 871954, England | Reg. Charity No.247257 | VAT No. 880 9924 76 |

Patron HRH The Prince of Wales, KG, KT, GCB